Iso 2768 Hole Tolerance H6

DIN ISO 2768 mk tolerances

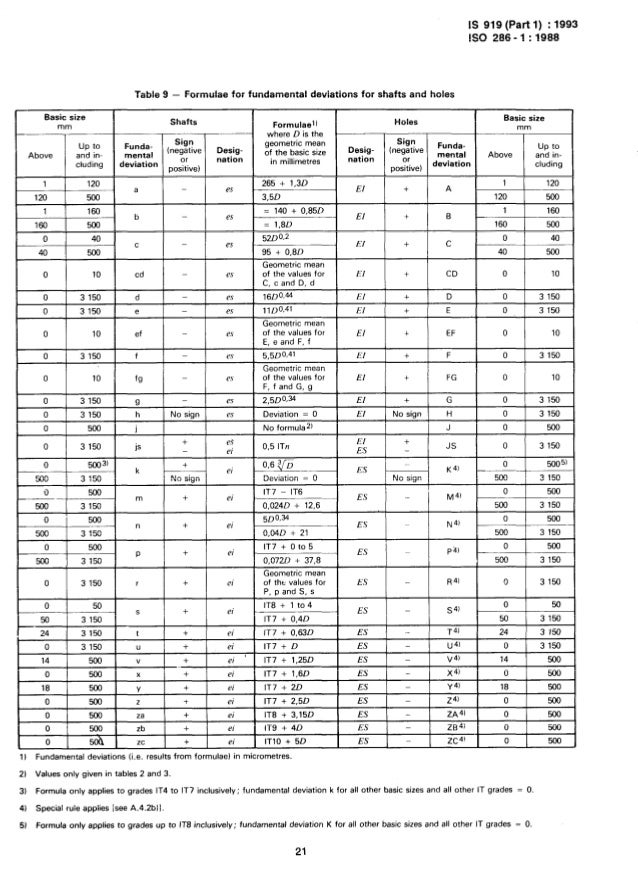

ISO Tolerances for Holes (ISO 286-2) ISO Tolerances for Holes (ISO 286-2) Nominal hole sizes (mm) over 3. H6 +8 0 +9 0 +11 0 +13 0 +16 0 +19 0 +22 0 +25 0 +29 0 +32 0 +36 0. H7 +12 0 +15 0 +18 0 +21 0 +25 0 +30 0 +35 0 +40 0 +46. ISO Tolerances for Holes(ISO 286-2)- 400mm to 3150 mm ISO Tolerances for Shafts(ISO 286-2)- 400mm to 3150 mm Remember - the information on this site is for general information purposes only and while we endeavour to keep the information up to date and correct, we make no representations or warranties of any kind, express or implied, about its.

Iso 2768 H7

Tolerance class General tolerances for straightness and evenness in mm Range of specified size in mm to 10 above 10 to 30 above 30 to 100 above 100 to 300 above 300 to 1000 above 1000 to 3000 H 0,02 0,05 0,1 0,2 0,3 0,4 K 0,05 0,1 0,2 0,4 0,6 0,8 L 0,1 0,2 0,4 0,8 1,2 1,6 Tolerance class General tolerances for straightness and evenness in mm Range of specified size in mm to 100 above 100 to 300 above 300 to 1000 above 1000 to 3000 H 0,2 0,3 0,4 0,5 K 0,4 0,6 0,8 1 L 0,6 1 1,5 2 Tolerance class General tolerances for symmetry Range of specified size in mm to 100 above 100 to 300 above 300 to 1000 above 1000 to 3000 H 0,5 K 0,6 0,8 1 L 0,6 1 1,5 2 General tolerances for form and position are valid for form elements for which form and position tolerances are not indicated individually. I am just quoting the job and I am still waiting on some answers from the company I got the drawings from. Even if it was in German I could work with the tables or have one or two locals translate for me. Something some engineer in training might use or perhaps a machining student might have access to? An M6 tolerance on a 47mm bore should be -4 to -20 according to my book. Practical Machinist is the easiest way to learn new techniques, get answers quickly and discuss common challenges with your peers.